Electronics Production

I decided I wanted to make a flexible PCB in anticipation of creating wearables. I began with a great online tutorial found here.

To begin with, I downloaded the following things.

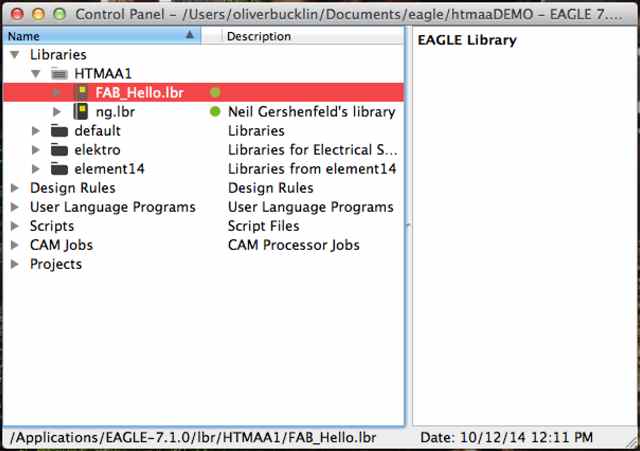

The basic components for the Fab ISP

these are not the current version of the class library, but things I found on Cynthia Mavros' page from 2012

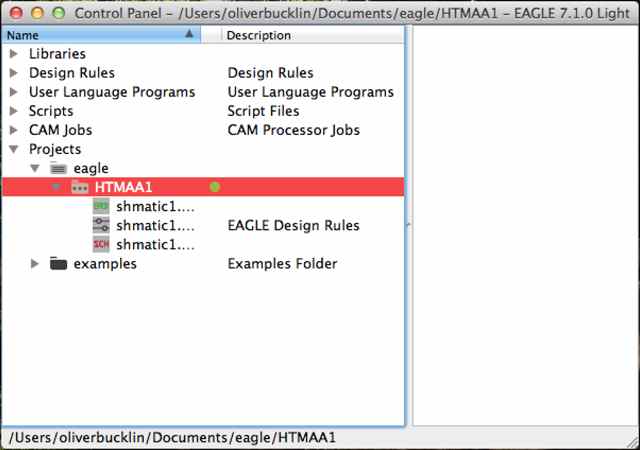

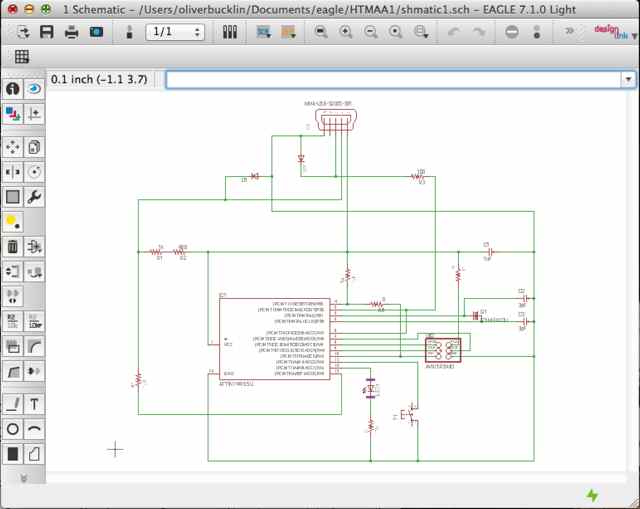

Once I got Eagle set up, I open it up and it looks like this.(minus the HTMAA1 project)

I started a new project(HTMAA1) and then loaded the .lbr files into the library folder in the Eagle folder.

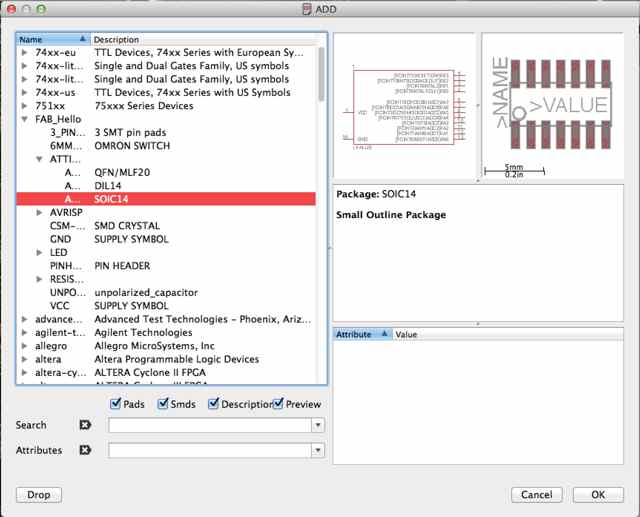

I started a new schematic, which came up as a blank document. I typed the "add" command and this window came up. I picked one of each of the parts in the fab_hello library, making sure to use the correct format of each component.

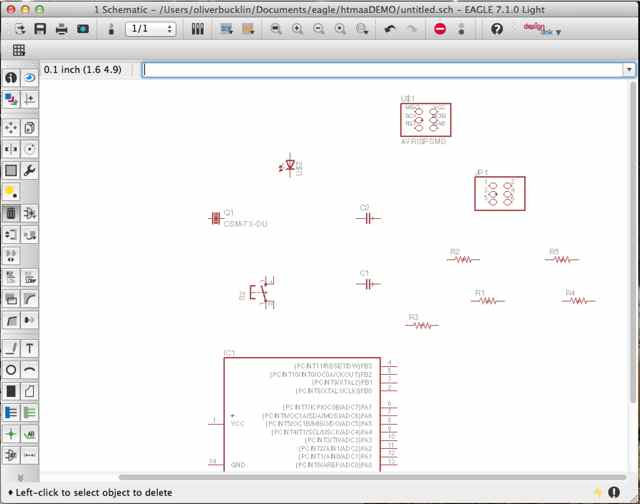

Once I had all the parts on the schematic, I used the "net" command to begin connecting them all.

I used the Fab_ISP that we already built as a model, using this diagram.

And this was my result!

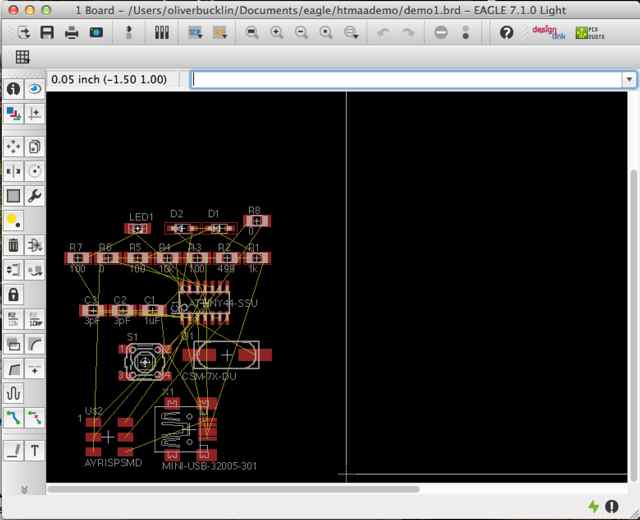

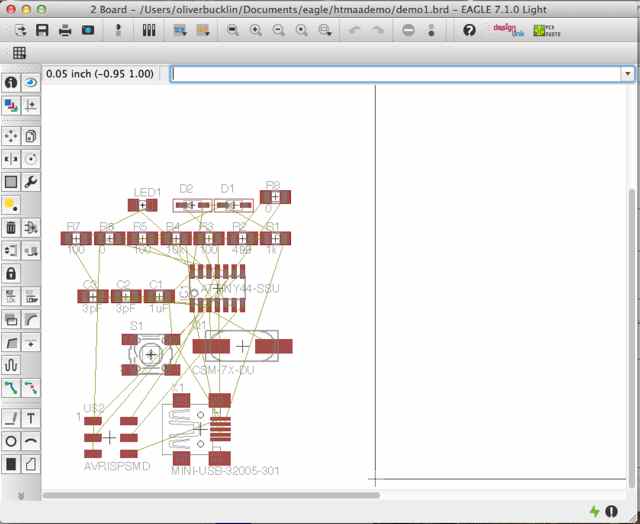

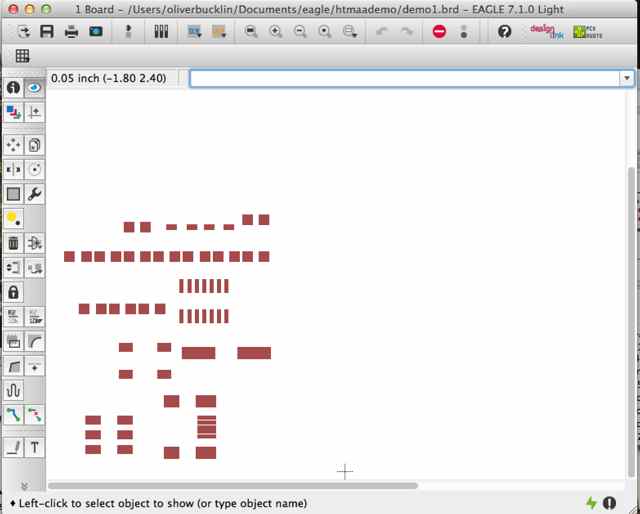

From here, I clicked the Create/switch to board button. Eagle gave me this jumble, withh all the components arranged by type... not very useful.

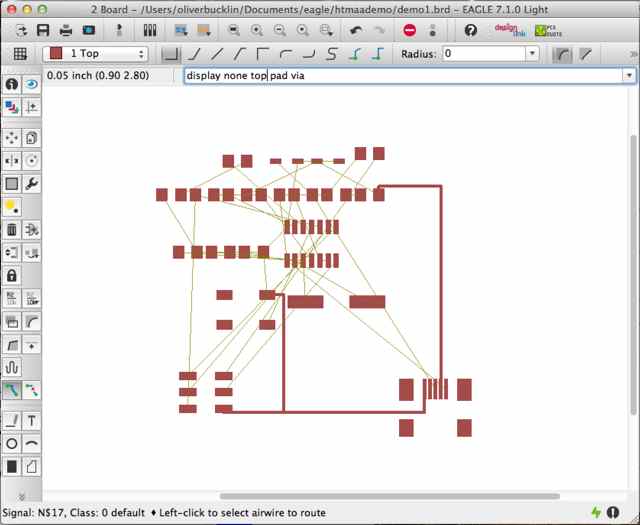

I used the command "set palette white" to get a white background

and "display none top pad via" to remove the components from the image for simpler routing.

Once I started routing, the basic connections showed up again. I liked using the command lines. Basically it's a puzzle, you just move rotate and route until everything fits and there are no unwanted shorts. To move components you have to turn them back on "display all"

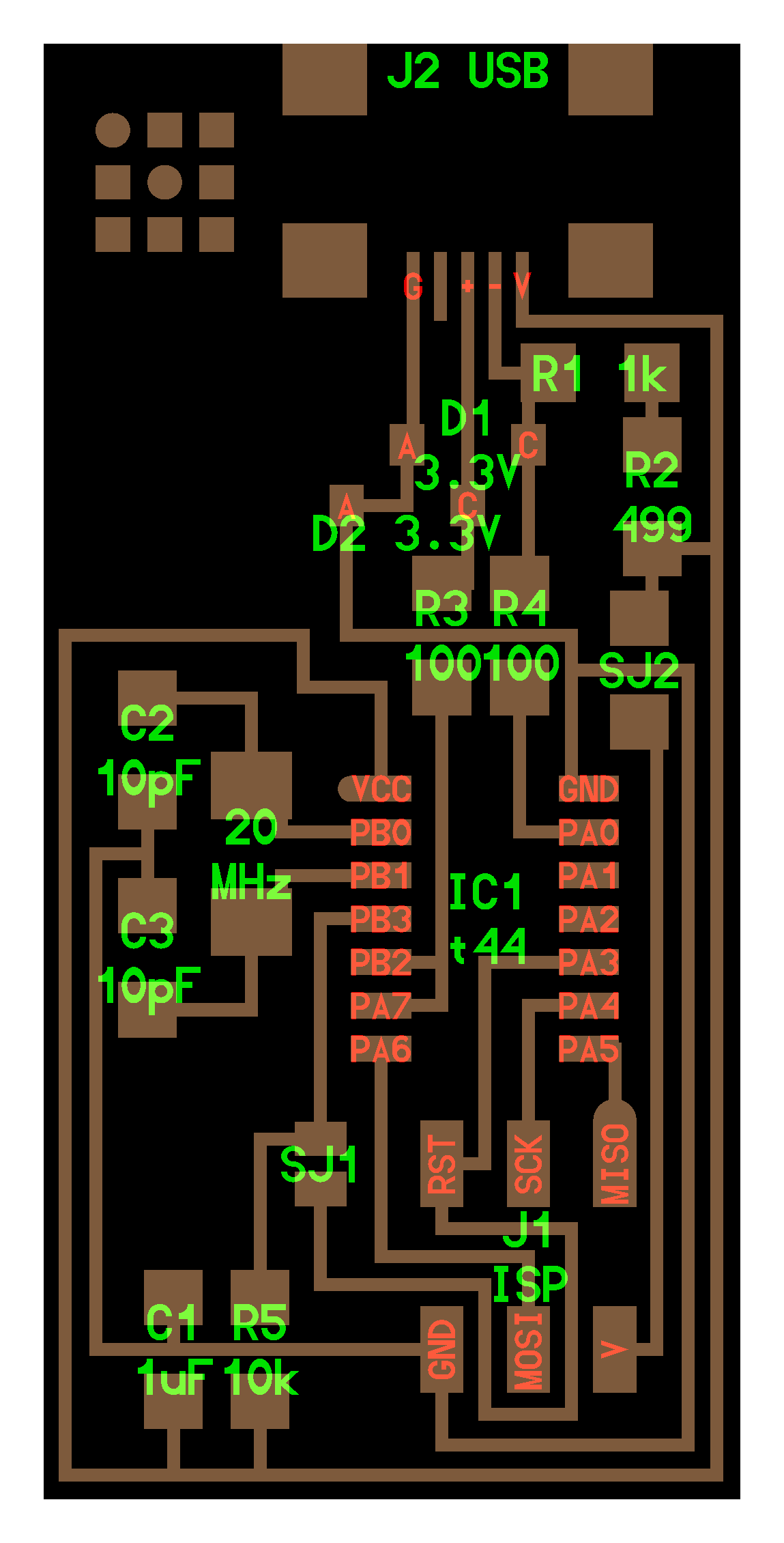

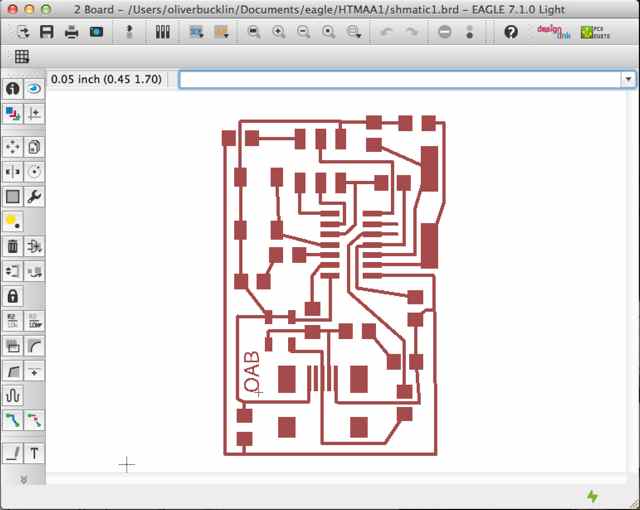

This was my final board in Eagle, which I exported as an image, monochromatic, 600dpi as a png. I used illustrator to draw a border, and then I tried to cut it out!

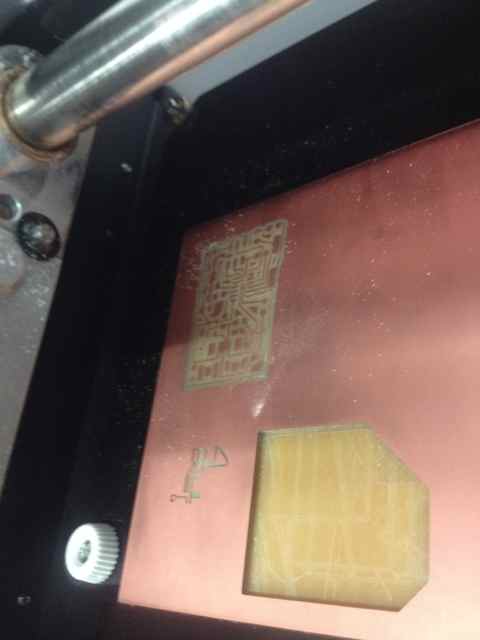

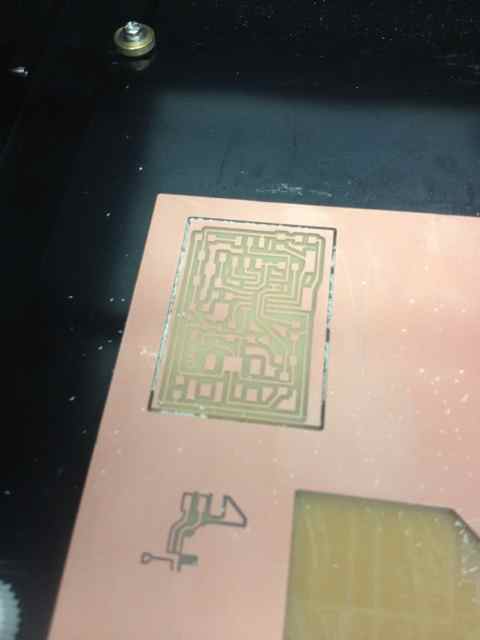

My first attempt to cut the copper foil didn't cut all the way through,

so I increased the force to 75, still no good. Finally at 90g pressure, the vinyl cutter managed to cut the foil, but then it started to tear and pull it up.

I slowed the knife speed and increased the trace width, but it was to no avail.

I might have packed my board too tightly...

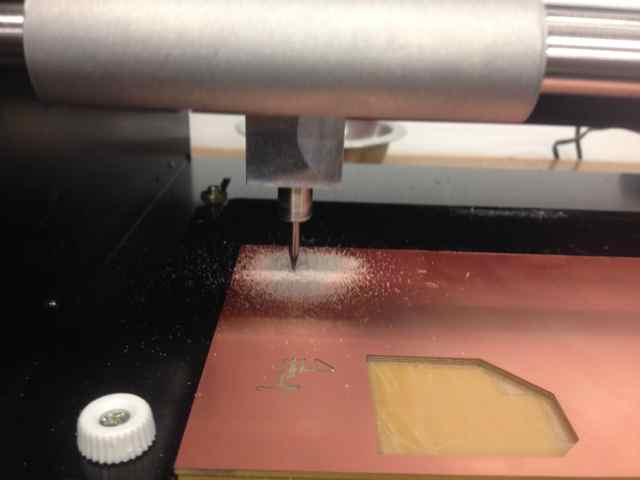

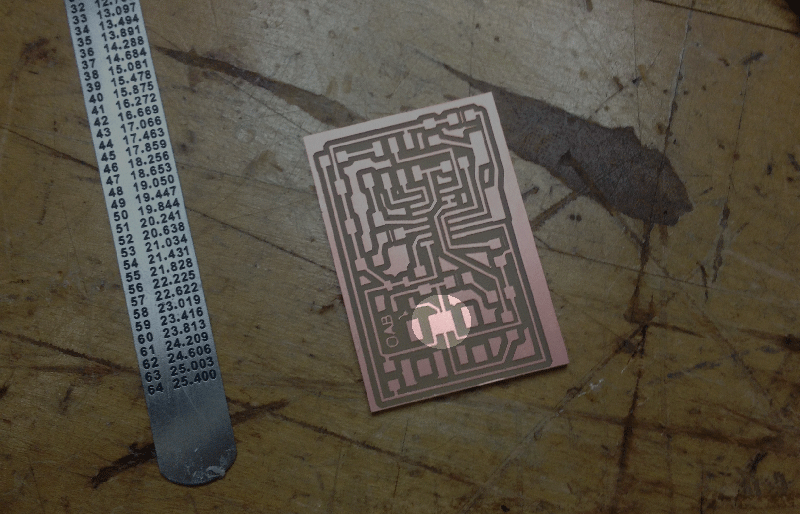

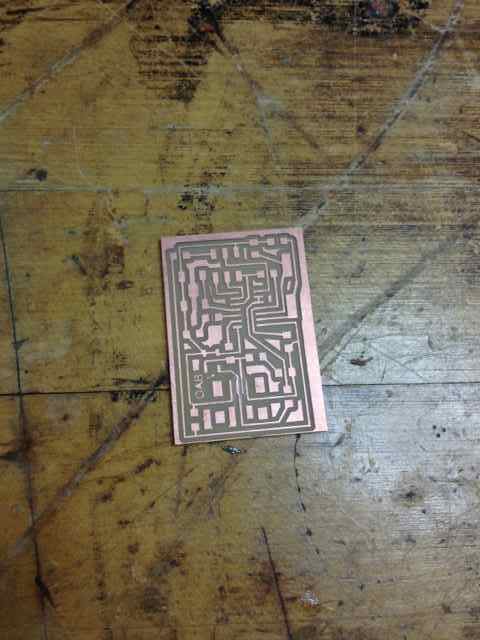

So then I milled the board, went really smoothly using the techniques from week2

Only problem was that the leads for the miniUSB header were too close to mill out, so I simply went in with an X-acto knife and straight edge and cut out the leads.

like so

and the finished board! For more on stuffing the board see this